SUMMARY

Magnetic fluid conditioning technology is not a new technology: but it has been uncommon, until now.

The magnetic field generated by the rare earth magnets used in MFC is powerful enough to reduce the viscosity of the crudes and improve the flowrates. In oil wells application, the magnetic treatment saw the softening and eventual disappearance of scale and hydrocarbon deposits (asphaltenes/wax) build-up on the tubing walls. Similarly for emulsions, fluid is segregated and ensures better crude quality. Positively, recurrence of these scales are eliminated or retarded to longer period. MFC tools can be accompanied by chemical treatment, to ensure 100% eradication of scale or waxy build-up.

TECHNOLOGY PRINCIPLES

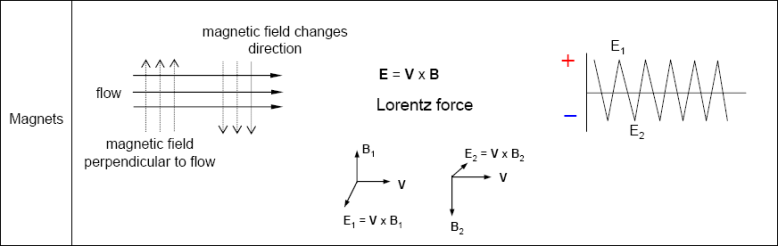

The technological basis for successful application of magnetic fields is not fully understood. There are several physical explanations believed to be the operative physical laws governing the effect of magnets on complex water and petroleum mixtures.

One theory proposes:

- A magnetic field affects the crystallization process whereby microcrystals are formed.

- Microcrystals do not bond with other crystals to form clusters.

- The net result is a deficiency of ions in solution, thus drawing ions from the deposits back into solution.

- As deposits dissolve, fluid movement erosion can also remove these impurities clusters.

OPERATING PRINCIPLES

- Rocha reports that when crude oil flows through an adequate magnetic field, the paraffin molecules tend to align their poles to the magnetic field, as long as thermal agitation is not excessive.

- When fluid, an aggregated form of ions, passes through the magnetic field, a force is exerted on each ion. The action of the magnetic field on these molecules changes both electron rotation and translation patterns, thus changing their orbital angular momentum.

- Magnetic field affects the crystallization process whereby microcrystals – insoluble compound – are formed.

- The magnetic treatment increases the coagulating tendency of the suspension ions by decreasing double-layer repulsion thus keeping microcrystals in solution and NOT allowing them to crystallize on the pipe walls. Microcrystals have weak bond and do NOT bond with other crystals and CANNOT precipitate out of fluid to form clusters (scales on the tubing walls).

- At the same time, the net result is a deficiency of ions in fluid, thus drawing ions from the existing deposits on the tubing walls, to re-enter back into solution/fluids (de-scaling process). Over time, these scales deposits dissolve and disappear, and will not form again;

These impurities will remain in the fluids, carried up to the tankfarms on the surface. - It is fairly well agreed that the anti-scale effect results from changes in crystallization behavior – promoting bulk solution precipitation rather than formation of adherent scale.

The Lorentz force influences the interaction of charged ions in the flowing fluid.

GENERAL BENEFITS

Like the Operators in America, the following results could be achieved by any Operator:

- Existing scales and hydrocarbon deposits (asphaltenes/wax) on the tubing walls melts away, layer by layer. Timeline to complete scale removal is highly dependent on the scale properties, crude properties, temperature and other working conditions. Normally, some results could be seen within 10 days of installation but there are cases where results are seen in 2-3 days.

- Emulsion build-up is expected to slow down and ultimately stopped.

- The separation process of oil and water, will be more efficient, as the two (2) fluids does not co-mingle as much. Removal of water below the oil is will be less tedious. The quality of oil will separator will be better as water contamination is less. Same time, other contaminants and impurities shall also be affected thus making flow more smooth over the length of the tubing and flowlines.

- The recurrence of these scales and deposits would happen, should there be other external forces such as pressure or temperature changes. These new “deposits” have weak bonds and altered molecular structure, and they are physically softer. With fast flowing fluids, the shear erosion of the rising fluids, over time, the build-up will soon disappear.

- The technology objective is to ensure RATE of EROSION > RATE of DEPOSITION

- Flowrates through the tubing will stabilize as tubing constrictions are removed. Over time, with other data constant, the well could revert to original design flowrates. Wellhead Pressures seen to stabilised and at times increased, as the constrictions are released;

- Downtime is also minimized as production is now regulated.

- Maintenance works, normally performed, are generally reduced and these are the main criteria why Texas Operators are opting for Flo-Rite tools.

- Workovers would be extended, as general maintenance work will be vastly reduced. Operators met, quoted workover extension from 15 months to 32 months. This massive cost savings makes the Flo-Rite MFC a key production and maintenance equipment for customers in Texas.

- Crude quality will be improved, as emulsion do not form. In Texas, a circulation system was also installed in the tank battery next to the production site. This guarantees the flowability of the crude during pumping into the main line.

- Surface Asset Lifecycle Extension – equipment life extended and maintenance decreased. Other indirect costs were also seen lowering including manpower, management control time and other related cost.

- As an enabler tool, corrosion inhibitors used becomes more effective and volume used is also lowered. As the deposits disappear downhole, the chemical injected reaches the target area better.

- The tools available are suited for both downhole applications as well as surface installation. This versatile design is customizable to suit to Operator configuration.

The tool benefits are sustainable – robust design, proven references, 100% Success…..